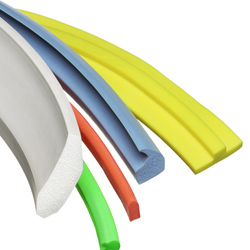

Silicone sponge strip offers many of the performance benefits associated with solid silicone, but in a softer and more compliant form.

Oriport Impex’ silicone expanded closed cell sponge strips are available in various widths and thicknesses and are available in a 50 meters roll or bought in minimum lengths and multiples of 5 metres. The strips are slit from sheet but are also available as an extrusion (skinned)

Expanded closed cell, silicone sponge strip offers many of the performance benefits associated with solid silicone, but in a softer and more compliant form. Silicone Sponge Rubber Sheeting and strips from Polymax Silicone range are available in various sizes, densities, colours and with self adhesive backing (SAB) on request.

Standard strips are available in an off-white (non-SAB) Sil 16 density.

Production – Most commercially available silicone sponge products are made from gum based polydimethylsiloxane (PMDS). The polymer is chemically expanded when heat cured to create the closed cell sponge structure. Closed cell means that the cells are non-interconnecting; therefore they do not allow water to wick through the sponge. Generally, silicone sponges have superior mechanical properties and are considered to have a complete closed cell structure. Expanded closed cell silicone sponge offers many of performance benefits of solid silicone in a softer and more compliant form.

Key Benefits of Closed Cell Silicone Sponge

Wide operating temperature – silicone sponge has a temperature range of -73°C to 250°C

Water sealing – the closed cell structure allows for good water sealing with relatively low compressive forces.

Compression set resistance – silicone offers excellent compression set resistance (ability to rebound to original thickness), especially at higher temperatures, compared to most rubber material. Low compression set silicone sponges are available for even better performance than general purpose grades.

UV and ozone resistance – silicone products have excellent UV and ozone resistance due in part to their inorganic backbone. This provides long term performance.

Rugged – when silicone is required, silicone sponge parts are more durable than some other products openly available.

Outdoor gasketing – considering all the above benefits, silicone sponge is a good material choice for outdoor environments, from the arctic to the desert.

We are among the reputed names in the industry for manufacturing and supplying Sponge Silicone Strips. The offered gaskets are exceptional in quality being made from high grade materials sourced from our highly reliable vendor base. They are extensively used in the automobile industry and are resistant to thermal expansion.

Features:

- Long lasting

- Used in automobiles

- Resistant to thermal expansion

- Dimensionally accuracy

- Superior finish

- Consistent physical properties throughout the length

- Optimum performance

- Long functional life

Specifications:

- Temperature range of: -80°C to 250°C

- Hardness of silicone Sponge Strip is 20 – 30 shore A.

- Diameter: 0.5 mm to 350 mm

Additional Information

Temp : -60 to 250 deg C

Elongation at break %: 200

Good ranking of Casino Affiliate Programs Review casino and sports betting affiliate programs, Super affiliate programs only with us, review, rating